Measuring Dryness Fraction of Steam. Control of Catalyst Activity in Reactors

The FIZEPR-SW100 dielectric moisture meter is modified for process media control at extreme temperatures.

Purpose:

- measuring of steam-water mixture composition (steam dryness fraction and moisture) in turbines and boilers at temperatures up to 374 ºC and pressures up to 220 bar and over;

- control of media phase state and composition in high-temperature chemical reactors;

- measuring parameters of powder and granular catalysts, control of their activity, coke formation monitoring;

- measuring the cryogenic liquid level in Dewar vessels.

____________________________________________________________________________________

An engineering solution implemented in the new design enables measurements of media featuring extreme temperatures and pressures without any changes in accuracy. Refer to Patent No. RU2576552 for description of the new analyzer design and measurement method:

An engineering solution implemented in the new design enables measurements of media featuring extreme temperatures and pressures without any changes in accuracy. Refer to Patent No. RU2576552 for description of the new analyzer design and measurement method:

http://fizepr.ru/sites/default/files/patent_2_576_552_n7.pdf

Summary of the invention: the microwave signal receiver and transmitter are  made as individual units connected by a uniform transmission line, e.g. by a cable. A primary transducer – probe – is connected to the middle section of the cable. It bypasses signal transmission by the cable when the transducer resonates.

made as individual units connected by a uniform transmission line, e.g. by a cable. A primary transducer – probe – is connected to the middle section of the cable. It bypasses signal transmission by the cable when the transducer resonates.

This enables resonance frequency monitoring at a distance from the measurement area with extreme conditions. The working range of sensor temperatures is now determined by allowable ceramics and probe metal temperatures only. The introduced update has virtually no any impact on the permittivity measurement accuracy εr. The accuracy of measurement is up to 4 significant digits.

This solution makes it possible to not only measure material compositions remotely, but also monitor liquid media levels at a distance, e.g. coolant level at nuclear power plants or liquid level in vessels under pressures of several hundred atmospheres. The patent on the moisture meter for extreme conditions is available at:

http://fizepr.ru/sites/default/files/patent_2_597_809_n10.pdf

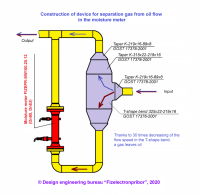

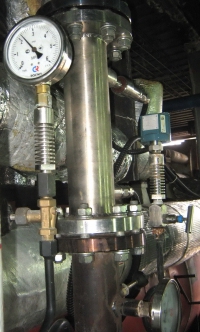

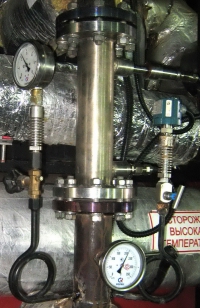

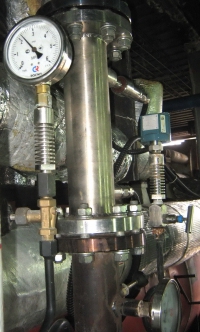

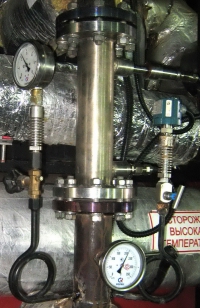

The photos show a steam dryness fraction meter made based on the referenced patents. The steam dryness fraction meter is used in the steam-generating plant operated at the high-viscosity oil field. Working pressure is 22bar, working temperature is about 220ºС, and dryness fraction of steam is about 90%.

The photos show a steam dryness fraction meter made based on the referenced patents. The steam dryness fraction meter is used in the steam-generating plant operated at the high-viscosity oil field. Working pressure is 22bar, working temperature is about 220ºС, and dryness fraction of steam is about 90%.

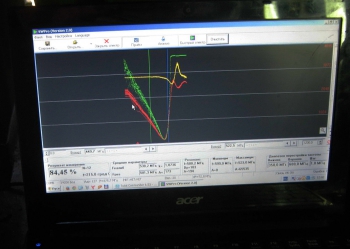

Steam-water mixture in the pipe was quite stable as seen from the given spectrum. The record was made during 10 minutes and spectra recorded at 1-minute intervals were nearly coincident.

___________________________________________________________________

Refer to an example below displaying the FIZEPR-SW100 analyzer application in catalyst activity control with the results of measuring four samples of KDM-M chromia-alumina powder catalyst used in synthetic rubber production. The samples were taken from the existing unit for dehydrogenation of isobutane to isobutylene. Only reference numbers of the samples were marked on the sample labels before testing.

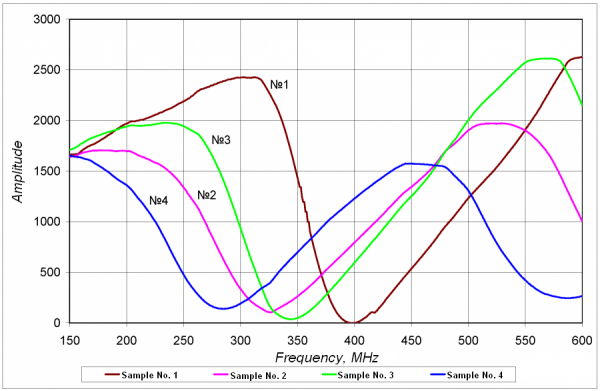

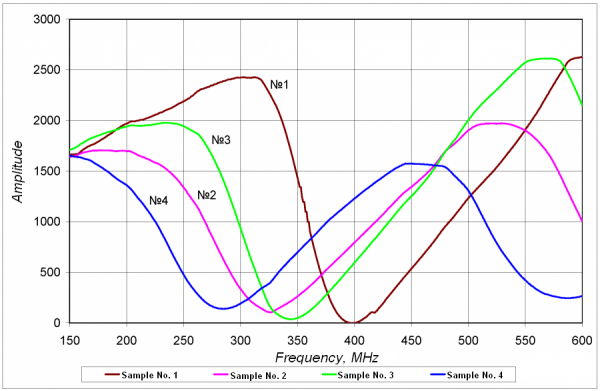

Measuring involves scanning a spectrum – frequency response of the sensor placed inside the material to be analyzed. The curves below show the measured spectra of Samples No. 1-4:

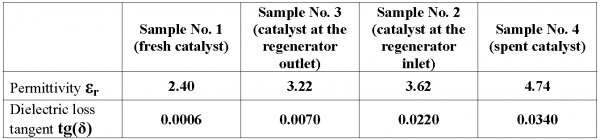

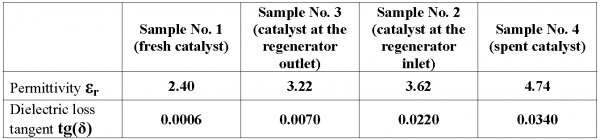

The FIZEPR-SW100 analyzer uses the spectra to identify dielectric parameters. The table below shows the results of measuring the catalyst dielectric parameters:

It appears that as the coke contaminates the catalyst, both its permittivity and dielectric loss tangent increase respectively.

Permittivity is increased by a factor of two (i.e. by 100 %); it is a dramatic change considering that the analyzer sensitivity is not worse than 0.06 % of the controlled parameter value.

Dielectric loss tangent of the samples changes by more than a factor of 50.

It should be noted that all types of catalysts based on aluminum and silicon oxides will produce the same results. The possibility to control the coke content is determined by the fact that the permittivity of coal and coke particles is significantly higher than the same of aluminum oxides and far higher than of silicon oxides, while the coal conductivity is greater than the conductivity of the materials specified by a number of times.

The FIZEPR-SW100 analyzer converts the dielectric parameters into the carbon ratio (or other value, e.g. the catalyst activity ratio) based on the calibration tables loaded in its memory. The calibration tables are compiled according to the results of catalyst sample measurements in a chemical laboratory.

Therefore, the FIZEPR-SW100 dielectric analyzer ensures a reliable monitoring of catalyst quality and activity directly in reactors at temperatures up to 800 ºС and higher.