The new series analyzers designed for measuring concentrations of salt, acid and alkali solutions is put into production. Analyzers can also be used as moisture meters, but they can also measure materials with high electrical conductivity, such as anthracite, sewage sludge, ion-exchange resins (ion-exchange polymer), etc. Analyzers are used for in-line control of materials as well as for measurements in tanks and laboratory studies.

The new series analyzers designed for measuring concentrations of salt, acid and alkali solutions is put into production. Analyzers can also be used as moisture meters, but they can also measure materials with high electrical conductivity, such as anthracite, sewage sludge, ion-exchange resins (ion-exchange polymer), etc. Analyzers are used for in-line control of materials as well as for measurements in tanks and laboratory studies.

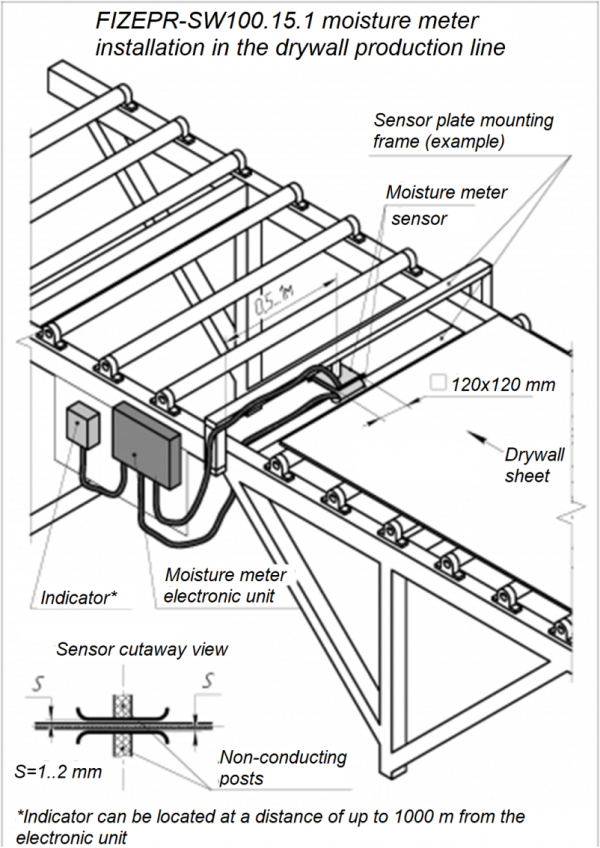

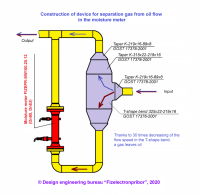

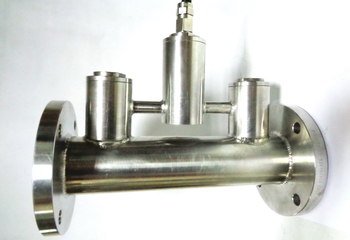

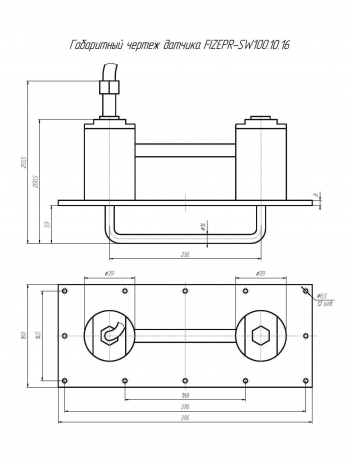

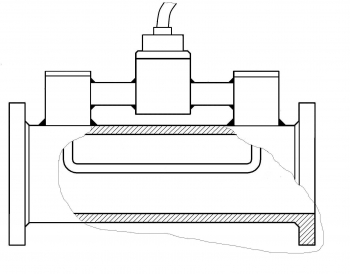

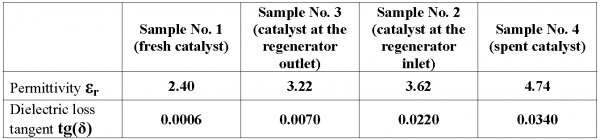

Sensors of analyzers in the in-line version are made for working pressures PN up to 160 bar and nominal bore DN from 50 to 150 mm.

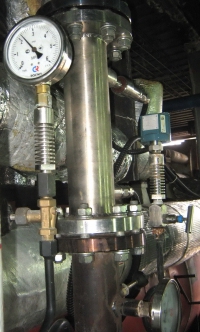

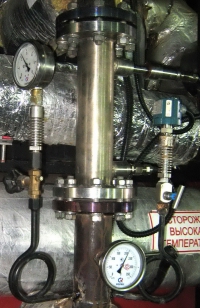

FIZEPR-SW100.27.6 (DN80, PN16) analyzer

FIZEPR-SW100.27.6 (DN80, PN16) analyzer

Concentration sensors shown in photos are the development of FIZEPR-SW100.20.х moisture analyzer series and made as a pipe with flanges. But these sensors can be manufactured in any version in which FIZEPR-SW100 moisture meters are made.

For example, the FIZEPR-SW100.11.6 analyzer can be used to measure concentrations of liquid and paste-like materials in tanks. The sensor of this analyzer contains a probe made as two parallel rods.  FIZEPR-SW100.11.6 and 11.41 sensors

FIZEPR-SW100.11.6 and 11.41 sensors

This sensor has a housing diameter of 48 mm and it can be used to control liquids in the measuring cylinder.

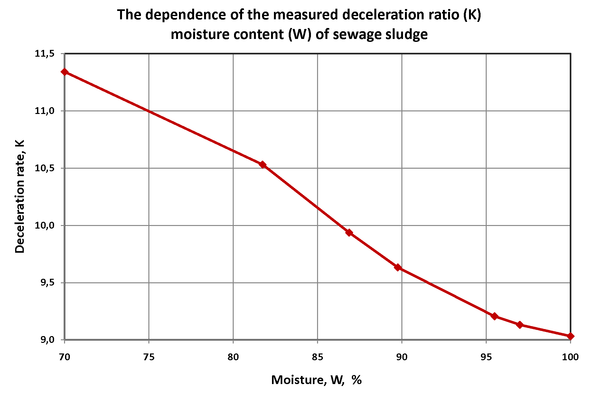

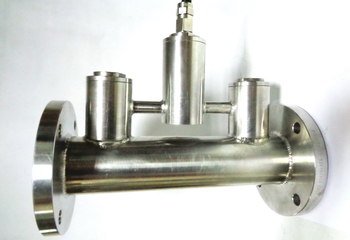

This sensor has a sealed design and can be secured on the pipe rod with the G1 straight pipe thread coupling. This sensor version can be used to control liquids in tanks including applications where wastewater sludge concentration measurements are required. Below is the calibration characteristic of a moisture meter for measuring sewage sludge.

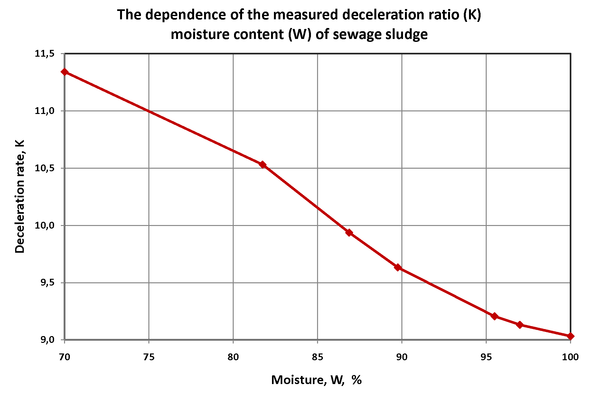

The FIZEPR-SW100.30.26 analyzer version replicates the laboratory version of the FIZEPR-SW100.30.2 moisture analyzer. The sensor is made as a measuring cell and can be used to analyze the composition of liquid, paste-like and bulk materials featuring high conductivity.

FIZEPR-SW100.30.26 analyzer

FIZEPR-SW100.30.26 analyzer

The operating principle of concentration meters manufactured by other companies is primarily based on measuring conductivity of the controlled material. However, instruments using this principle (conductivity meters) are not suitable for measurements at high conductivity. For example, the usable range of caustic solution (NaOH - sodium hydroxide) concentration standard for VALMET concentration sensors is limited by a value of 20%.

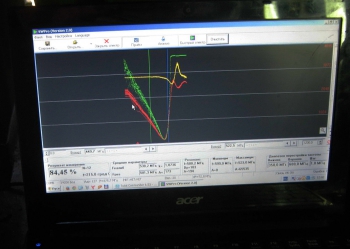

FIZEPR-SW100 analyzers have a substantially greater range of measurements. As shown in the chart, sodium hydroxide measurements are provided in the range up to 40% at temperatures over 100ºС.

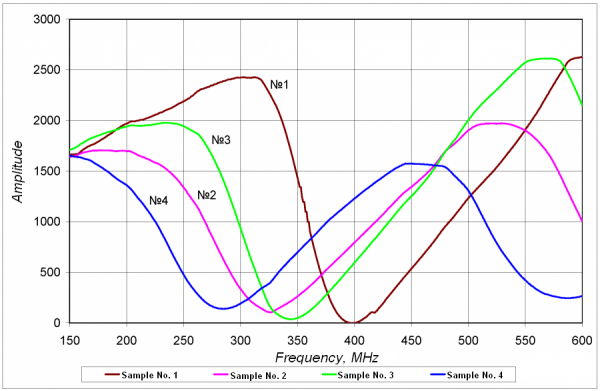

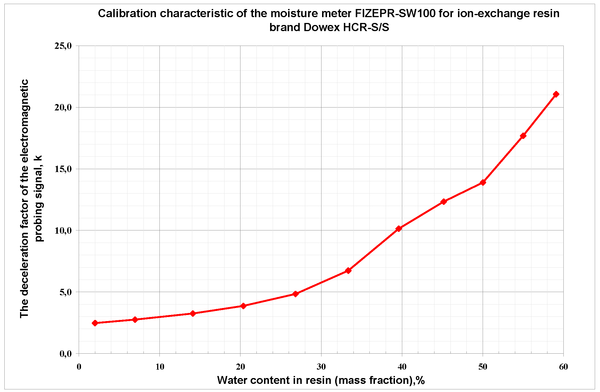

Similarly to all FIZEPR-SW100 series moisture meters produced, new instruments have a radio wave measurement principle based on electromagnetic velocity measurement. Deceleration factor k of the electromagnetic wave also called refractive index is determined during measurement. This factor is calculated as a ratio of wave velocity in air (speed of light) to the speed of electromagnetic wave distribution in the controlled material. For ordinary materials (with low conductivity) this factor is equal to the square root of permittivity and ranges between 1 and 10. For high-conductivity materials deceleration factor rises sharply and can reach values as high as hundreds of units.

Sensors of analyzers FIZEPR-SW100.27.6 and FIZEPR-SW100.27.14 FIZEPR-SW100 concentration meters can be used for in-line concentration control of sulfuric acid and other acids as well as alkali solutions and for measuring salt content in salt slurry.

Sensors of analyzers FIZEPR-SW100.27.6 and FIZEPR-SW100.27.14 FIZEPR-SW100 concentration meters can be used for in-line concentration control of sulfuric acid and other acids as well as alkali solutions and for measuring salt content in salt slurry.

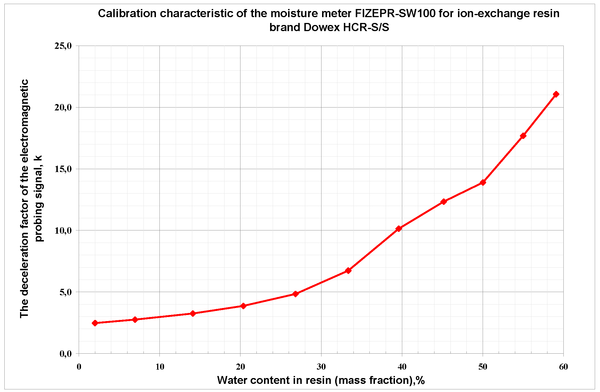

It is possible to use these analyzers to control the water content in ion-exchange resins. For example, in the technological processes of recovery of spent ion-exchange resins to control the removal of excess water. Another new application is gelatin moisture control in digesters.

It should be noted that due to the high electrical conductivity of ion-exchange resins (as well as anthracite, gelatin, etc.), the use of conventional moisture meters on such materials is impossible.

The test of the new measurement principle was performed on an ion-exchange resin of the brand Dowex HCR-S/S. The measurements were performed with two types of moisture meters: FIZEPR-SW100.30.26 and FIZEPR-SW100.11.6.

Ion-exchange resin, sensor FIZEPR-SW100.30.26

Ion-exchange resin, sensor FIZEPR-SW100.30.26 Ion-exchange resin, sensor FIZEPR-SW100.11.6

Ion-exchange resin, sensor FIZEPR-SW100.11.6

Below is a graph of the calibration dependence of the ion-exchange resin moisture meter. Devices provide reliable measurements of moisture content and can be used both in production and in technological processes using ion-exchange resins, as well as in the process of resin regeneration.

The developed measurement principle is protected by patents.