Moisture meters for high-conductivity materials

A new series of moisture analyzers (moisture meters) is designed to measure materials with high electrical conductivity such as salts, chemical sludge, sewage sludge, anthracite, ion exchange resins, etc. These analyzers can also be used to measure concentrations of salt, acid and alkali solutions.

Moisture meter FIZEPR-SW100.10.46 for hopper

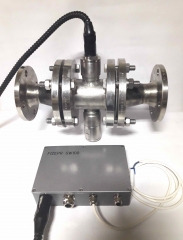

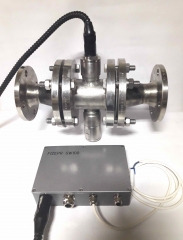

Moisture meter FIZEPR-SW100.10.46 for hopper  FIZEPR-SW100.27.6 (DN80, PN16) analyzer

FIZEPR-SW100.27.6 (DN80, PN16) analyzer

These new analyzers are designed to monitor materials in the flow, for measurements in tanks and on conveyor belt, as well as for laboratory studies.

Sensors of in-line analyzers are available for operating pressures PN up to 160 bar and nominal diameters DN from 50 to 150 mm. The moisture measurement range is 0 to 100%.

FIZEPR-SW100.10.56 moisture meter for conveyors

FIZEPR-SW100.10.56 moisture meter for conveyors

FIZEPR-SW100.27.x sensors shown in the photos are an improved version of FIZEPR-SW100.20.x moisture meter series and are made as a pipe with flanges. However, these sensors can be made in any designs in which FIZEPR-SW100 series moisture meters are manufactured.

For example, the FIZEPR-SW100.11.6 analyzer can be applied to measure concentrations of liquid and paste-like materials in vessels. The sensor of this analyzer has a probe made in the form of two parallel rods.

The housing diameter of this sensor is 48 mm, which makes it possible to be used for monitoring liquids in measuring cylinders. The sensor has a sealed design and can be fixed to the stem pipe by means of a coupling with the G1 straight pipe thread.  FIZEPR-SW100.11.6 and

FIZEPR-SW100.11.6 and

11.41 sensors

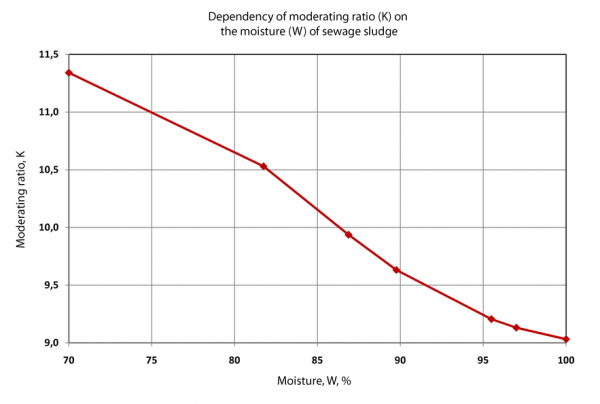

In this version, the sensor can be used to monitor liquids in tanks including for measuring sewage sludge concentration (or moisture content). Below is a moisture meter calibration graph for sewage sludge measurement.

The FIZEPR-SW100.30.26 moisture meter version repeats the laboratory version of the FIZEPR-SW100.30.2 moisture analyzer in terms of its design features. The sensor is made as a cuvette and can be used to analyze the composition of high conductivity liquid, paste-like and bulk materials.

FIZEPR-SW100.30.26 sensor

FIZEPR-SW100.30.26 sensor

In general, the operating principle of concentration meters manufactured by other companies is based on measuring the electrical conductivity of the controlled material. However, devices based on this principle (conductivity meters) do not provide measurements at high electrical conductivity. For example, the measurement range of caustic solution concentration (NaOH - sodium hydroxide) for VALMET concentration sensors is limited to 20% at high temperatures.

In the FIZEPR-SW100 concentration analyzers, the measurement range is significantly expanded. For sodium hydroxide, as can be seen from the graph, measurements are provided in the range of up to 40% at temperatures above 100 °C.

As for all FIZEPR-SW100 series analyzers manufactured, the measurement principle of new devices is radio wave and is based on measuring the electromagnetic wave propagation velocity. When measuring, the deceleration coefficient k of the electromagnetic wave is determined, also called the refractive index.

This coefficient is calculated as the ratio of the wave velocity in the air (light velocity) to the electromagnetic wave propagation velocity in the material controlled. For ordinary materials (with low electrical conductivity), this coefficient is equal to the square root of permittivity and ranges from 1 to 10. For materials with high electrical conductivity, the deceleration coefficient increases sharply and can reach values of hundreds of units.

FIZEPR-SW100.27 concentration meters (moisture meters)

FIZEPR-SW100.27 concentration meters (moisture meters)

The FIZEPR-SW100 series analyzers can be used for monitoring the flow of acids, alkali solutions, as well as for measuring the salt content in salt pulp.

These analyzers may also be used to measure the water content in ion-exchange resins in spent ion-exchange resin recovery processes where excess water is removed. Another new application is measuring the gelatin moisture content in digesters.

It should be noted that due to the high electrical conductivity of ion-exchange resins (anthracite, gelatin, etc.), the use of conventional moisture meters in such materials is impossible.

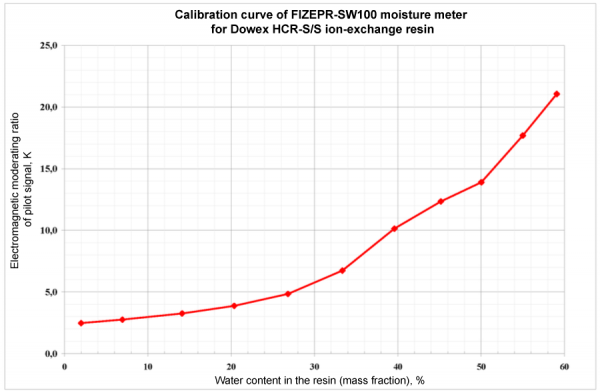

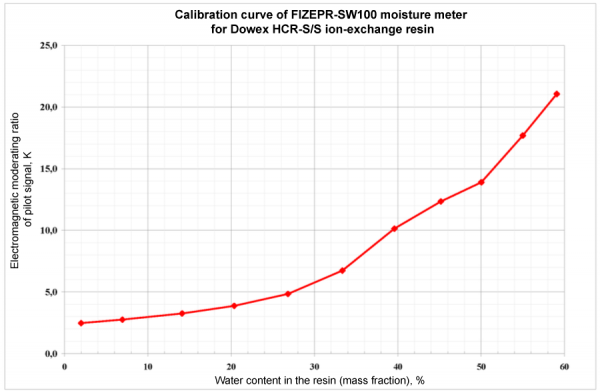

The new measurement principle was tested on the Dowex HCR-S/S ion exchange resin (a strong acid cationite based on a sulfonated copolymer of styrene divinylbenzene in sodium form). The measurements were carried out by two types of sensors: FIZEPR-SW100.30.26 and FIZEPR-SW100.11.6.

Ion-exchange resin,

Ion-exchange resin,

FIZEPR-SW100.30.26 sensor  Ion-exchange resin, FIZEPR-SW100.11.6 sensor

Ion-exchange resin, FIZEPR-SW100.11.6 sensor  FIZEPR-SW100.21.16 moisture meter

FIZEPR-SW100.21.16 moisture meter

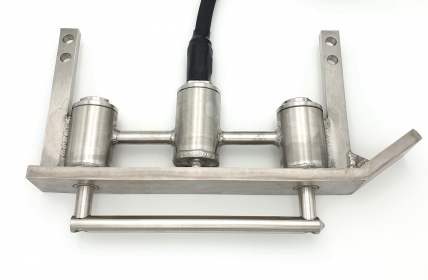

The FIZEPR-SW100.21.16 moisture meter was manufactured following the results of the studies ordered by EcoSater Systems, USA.

It is used in the production of filters containing ion exchange resin. Moisture meters of this type provide reliable moisture content measurements and can be used both in production and in process operations using ion-exchange resins, as well as in the process of resin regeneration.

The calibration curve of moisture meters on ion exchange resin is shown below.

Moisture measurement of anthracite, iron ore concentrate and salts

The moisture meters of the FIZEPR-SW100.10.16 and 10.56 series were originally developed for specific tasks: for measuring the humidity of sylvinite, carnallite, coal (anthracite), iron ore concentrate and NaCl and KCl salts.

FIZEPR-SW100.10.56 moisture meter

FIZEPR-SW100.10.56 moisture meter  FIZEPR-SW100.10.16 moisture meter (explosion-proof design)

FIZEPR-SW100.10.16 moisture meter (explosion-proof design)

These meters can also be used to control other high conductivity bulk materials, like potash moisture meters, soda moisture meters, aluminum hydroxide moisture meters, ore moisture meters, potassium salt moisture meters, etc. Moisture meters of the new type can be used to measure the moisture of materials with magnetic properties, including, as mentioned above, as iron ore concentrate moisture meters.

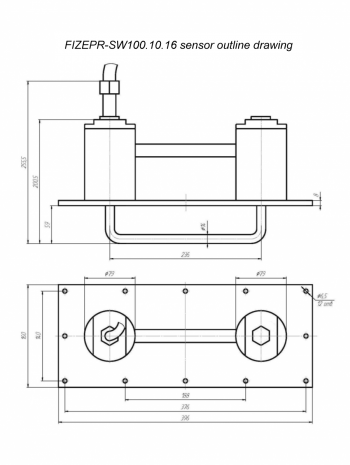

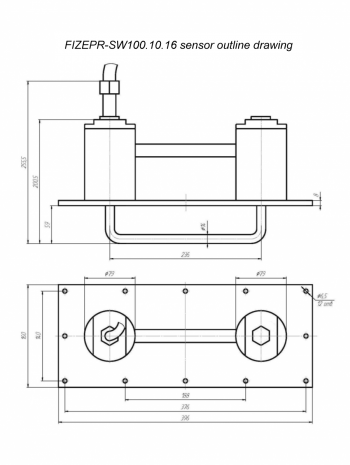

FIZEPR-SW100.10.16 sensorThe FIZEPR-SW100.10.16 moisture sensor is similar in its design to the widely used bulk material sensor of the FIZEPR-SW100.10.6 version and is also installed in hoppers and on conveyor belts. However, in case of highly abrasive controlled materials, FIZEPR-SW100.10.56 moisture meters are used for measurements on conveyors as their sensors are made of steel resistant to abrasive wear (HARDOX, 95X18, C-500).

FIZEPR-SW100.10.16 sensorThe FIZEPR-SW100.10.16 moisture sensor is similar in its design to the widely used bulk material sensor of the FIZEPR-SW100.10.6 version and is also installed in hoppers and on conveyor belts. However, in case of highly abrasive controlled materials, FIZEPR-SW100.10.56 moisture meters are used for measurements on conveyors as their sensors are made of steel resistant to abrasive wear (HARDOX, 95X18, C-500).

Unlike the FIZEPR-SW100.10.6 and FIZEPR-SW100.10.5 versions used only on low conductivity materials, the new moisture meters provide measurements at almost any electrical conductivity of the controlled material.

The FIZEPR-SW100.10.16 sensor is made of 12Kh18N10T abrasion-resistant stainless steel. For moisture meters installed on the conveyor, the probe is made of an alloy according to the technology used in the manufacture of drill bits, which provides exceptionally high abrasion resistance for use with abrasive materials.

The rest features of FIZEPR-SW100.10.16 and 10.56 moisture meters are the same as those of the well-known FIZEPR-SW100.10.6 and 10.5 versions. They use the same permittivity measurement principle.

The measured volume of the controlled material is 10...15 liters. Thanks to such a large volume of the material analyzed it is possible to exclude the impact of heterogeneity in the moisture distribution in the material, eliminate any effects of loose fit of the material to the sensor thus allowing measurement of materials with fraction sizes up to 3 cm.

For moisture content measurements of coal and other explosive materials, moisture meters are available in explosion-proof design.

The moisture meter is available in the FIZEPR-SW100.10.166 version for measuring materials at temperatures up to 200 °C. Electronics are separated from the high-temperature area in the sensor of this moisture meter.

FIZEPR-SW100.10.166 sensor for high temperatures

FIZEPR-SW100.10.166 sensor for high temperatures  FIZEPR-SW100.10.16 moisture meter with a control box

FIZEPR-SW100.10.16 moisture meter with a control box

At the time when the manufacturing of moisture meters for bulk materials was launched, FIZEPR-SW100.27.x series moisture meters with a similar principle were put into production for measurements in the flow of a suspended mixture of sodium chloride and other high conductivity liquid materials in pipelines.

The FIZEPR-SW100.27.x moisture meters can be used to control sludge in cement production, to measure the composition of coal-water fuel (CWF), to control the composition of salt pulp (measurement of the ratio of solid and liquid phases in the pulp flow).

FIZEPR-SW100.27.4 moisture meter for salt pulp (with DN80 - DN50 adapters)

FIZEPR-SW100.27.4 moisture meter for salt pulp (with DN80 - DN50 adapters)

All the above moisture meters have a water content measurement range of 0 to 100%.

The devices operate at almost any salt content and with materials featuring high magnetic permeability.

Below are photos of the FIZEPR-SW100.30.26 laboratory sensor where its cuvette is filled with iron ore concentrate. The measurements are stable in the range from dry material to liquid suspension where the concentrate, as can be seen from the attached photo, is under a layer of water.

Concentrate, W=13%

Concentrate, W=13%  Concentrate, W=10%

Concentrate, W=10%  Concentrate, W=15,7%

Concentrate, W=15,7%

The measurement principle for high conductivity materials implemented in the moisture meters manufactured is protected by international patents.