Moisture meter FIZEPR-SW100.17.X for concrete-mixing machines

FIZEPR-SW100.17.X series microwave moisture meters are mainly designed for measuring moisture in concrete mixers.

Boring bit manufacturing technology was used in the sensors production to provide performance in such rough conditions. Protective coating of tungsten carbide (or chromium-adamantine coating) was applied on surface of the sensors, and the sensors themselves are made of extra hard alloy. Like boring cutters, manufactured with the same technology, FIZEPR-SW100.17.X sensors are characterized by high resistance to abrasive wear and impacts.

This solution is a successful alternative to traditional use of ceramic plates in the design of sensors for concrete mixers.

Replacement of ceramics with this alternative provided sensor impact resistance and, more importantly, allowed to increase moisture meter sensitivity, probing depth (due to removal of ceramic layer from the area scanned by microwaves). Comparative tests proved this statement. Differences in FIZEPR-SW100.17.X sensors sensitivity and ceramic plate sensors sensitivity are especially notable when used in stiff mixtures.

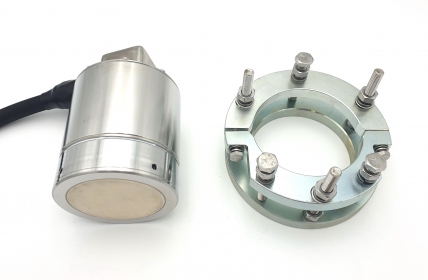

FIZEPR-SW100.17.12 with mounting fittings

FIZEPR-SW100.17.12 with mounting fittings  Microwave moisture meters FIZEPR-SW100.17.12 series with ceramic disk made of silicon nitride

Microwave moisture meters FIZEPR-SW100.17.12 series with ceramic disk made of silicon nitride

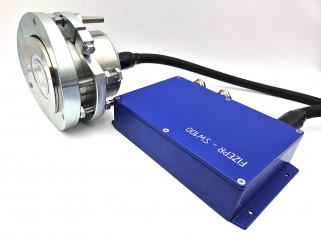

Moisture meter electronics are incorporated in individual electronic module providing convenience of maintenance and improving meter reliability

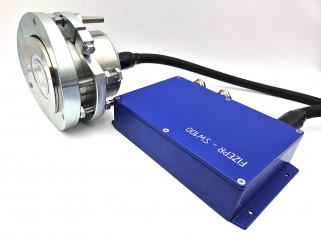

Sensor of FIZEPR-SW100.17.8 moisture meter in assembly with an electronic module

Sensor of FIZEPR-SW100.17.8 moisture meter in assembly with an electronic module  FIZEPR-SW100.17.85 moisture meter in assembly with an electronic module

FIZEPR-SW100.17.85 moisture meter in assembly with an electronic module

Thermistors allowing controlling concrete mixture temperature are installed in FIZEPR-SW100.17.X sensors casing. Temperature value is automatically included in concrete mixture moisture calculation.

Videos showing the use of moisture meters in industry can be found here: YouTube. The general catalog of moisture meters for bulk and pasty materials, including moisture meters for concrete mixers, is given here: Catalog

FIZEPR-SW100 moisture meter design, method of measurement and mathematical methods of measurements processing are protected with 12 patents, both Russian and foreign ones.

Invention descriptions are available at: http://fizepr.com/patenty

MEASUREMENTS PROCESSING AND OUTPUT

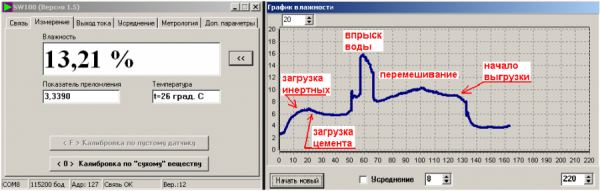

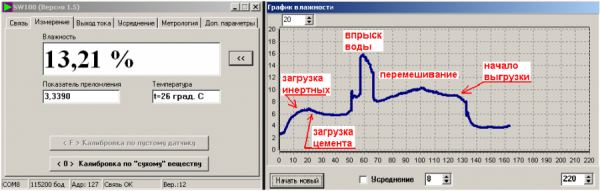

FIZEPR-SW100.17.X moisture meters incorporate a microprocessor with a wide range of signal processing abilities. Processor software allows preventing affecting of measurements by movement of concrete mixer blades near the sensor surface. It is well seen on the concrete production cycle diagram.

Recording at the recorder of the cycle of preparation of concrete

Recording at the recorder of the cycle of preparation of concrete

Measurements are made with 0.2 sec interval. Moisture meter is equipped with two output communication channels to transfer measurements: digital (MODBUS RTU, RS485) and analogue (4-20 mA). This solution allows incorporating the moisture meters in quick-release devices automatic control system.

For concrete production control, it is recommended to display the data on a graphical recorder or a PC (laptop), which allows an operator to monitor the process dynamically, thus making production cycle shorter and improving concrete quality.

DESIGN AND VERSIONS

When installed into concrete mixers, FIZEPR-SW100.17.X sensors are fixed in holes located in mixer bottom or walls. All fixtures required are included in the package.

Sensors of FIZEPR-SW100.17.X moisture meters are available in two basic versions with different casing diameter and dimensions:

- Casing diameter of FIZEPR-SW100.17.8 and FIZEPR-SW100.17.7 sensors: 108 mm;

- Casing diameter of FIZEPR-SW100.17.1 and FIZEPR-SW100.17.2 sensors: 80 mm.

FIZEPR-SW100.17.8 and FIZEPR-SW100.17.1 moisture meters with a mounting kit

FIZEPR-SW100.17.8 and FIZEPR-SW100.17.1 moisture meters with a mounting kit

FIZEPR-SW100.17.X sensors can be used on the assembly line: here, sensor is fixed on skid, as shown in the photo.

FIZEPR-SW100.17.8 sensor on the assembly line

FIZEPR-SW100.17.8 sensor on the assembly line  FIZEPR-SW100.17.8 sensor on the assembly line

FIZEPR-SW100.17.8 sensor on the assembly line

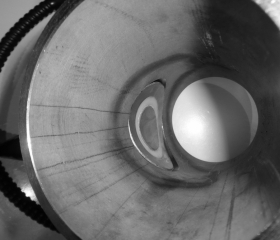

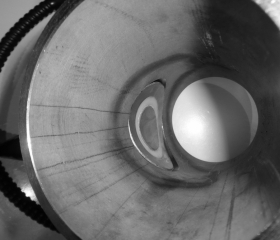

FIZEPR-SW100.17.8 , - 17.1 and -17.7 sensors are equipped with a flat probe. In FIZEPR-SW100.17.2 sensor, probe surface is made with 50 mm curve radius, which allows incorporating of the sensor into sampling systems for 100 mm diameter pipe.

FIZEPR-SW100.17.2 analyzer sensor in the sampling system

FIZEPR-SW100.17.2 analyzer sensor in the sampling system  FIZEPR-SW100.17.2 sensor in the 100 mm diameter pipe

FIZEPR-SW100.17.2 sensor in the 100 mm diameter pipe

FIZEPR-SW100.17.X moisture analysers can be used not only in concrete mixtures but in other spread and bulk materials. The specified moisture meters remain functional in highly conductive materials as well, such as coal and iron-ore concentrate at moisture up to 5%. However for measurement of the specified materials with moisture up to 5% (and other highly conductive materials), “Fizelectonpribor” Design Bureau established production of FIZEPR-SW100.10.16 moisture meters. Description is available at: http://fizepr.com/news/moisture-meters-coal-anthracite-iron-ore-concentrate-salt-and-other-high-conductivity-materia-0

FIZEPR-SW100.17.X moisture meters are released both in general purpose industrial version and explosion-proof version. Electronic module of an explosion-proof moisture meter is marked as 1Exd[ia]IIBT5, and sensor is marked as 0ExiaIIBT5. The sensor is classified as highly explosion-proof electrical equipment and can be installed in potentially explosive environments of any category.

FIZEPR-SW100.17.8 of an explosion-proof moisture meter

FIZEPR-SW100.17.8 of an explosion-proof moisture meter