Microwave barrier level sensors SIUR-03V

The microwave barrier SIUR-03V is especially adapted to the requirements and needs of the bulk solids industry. The measurement is non-contact and the sensor itself has no direct contact with the medium. This is advantageous particularly for abrasive media or very high temperatures. In such cases, SIUR-03V can simply measure from the outside, through a microwave permeable window, e.g. of ceramic. Housings of stainless steel as well as different antenna systems and process fittings are at the user's disposal. He can thus configure the sensor to meet exactly his requirements.

First samples of microwave sensors SIUR-03V were made in Design Bureau "Fizelektronpribor" in 1997 by the request of "Fosfor" (Togliatti) for installation on burden material kilns instead of radioisotope sensors.

The SIUR-03V sensors are highly reliable, they do not have items subjected to wear and thereby limiting the service lifetime. The microwave barrier SIUR-03V are installed in such a way that there are no sensor elements in the tank. This allows using them on materials with oversize particles (ore, crushed stone, etc.).

Compared with rotary and vibrating alarms applicable until the present time, microwave sensors are not sensitive to material adhering, resistant to abrasive effect and do not need any maintenance. Microwave signal passes freely through the flow of rolling material, which allows using sensors SIUR-03V in any dust conditions, including the time of bulk product loading.

Another advantage of the microwave barriers SIUR-03V is operating in environments with extreme temperatures. Alarms have been widely used in wood waste boiler plants for control and automatic adjustment of burning fuel level.

The SIUR-03V barrier is reliable, resistant to radio frequency and line interferences. It does not require maintenance, and is completely safe for personnel compared with radioisotope sensors.

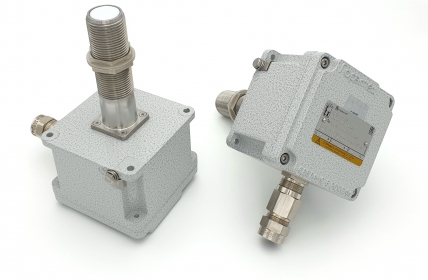

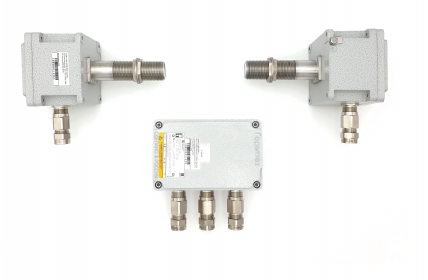

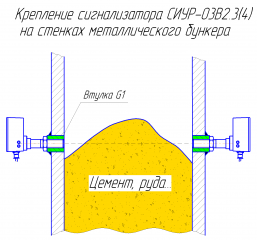

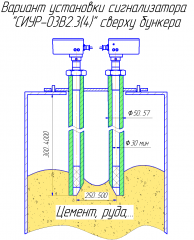

The sensor modifications SIUR-03V2.3 and SIUR-03V2.4 were specially designed to control the amount of cement in pressurized silos of concrete products plants.

The SIUR-03V2.4 version differs from SIUR-03V2.3 only by the method of connecting cables: sealed lead-ins are used instead of bolt connectors.

In a silo with cement fill the level is generally controlled in its lower (to indicate the need of loading the new material) or top (to prevent silo overflow during loading) part. Silos of more than 60 m3 volume sometimes have sensors in their middle part. The cement layer of 15 cm thickness adhering to the walls of the silo and on the sensor surface does not affect the operability. In order to register the presence of cement the sensor requires a thicker material layer at the control level, for example 40 - 50 cm.

Allowable extreme pressure for the sensors SIUR-03V2.3 and SIUR-03V2.4 is 10 atm.

Warranty period for all sensors SIUR-03V2 is 24 months.

The SIUR-03V barriers are used at Russian factories in the following cities: Tver, Kovrov, Kostomuksha, Penza, Yuryuzan, Alapayevsk, Ust-Ilimsk, Chelyabinsk and many others, and have positive reviews.

Operating principle of alarm

The barrier of level consists of transmitting and receiving modules, which are mounted on opposite walls of the tank at a control level. Radiation and reception of radio waves by antennas are made through the holes in the tank walls.

Transmitter (TR) radiates radio waves into the tank via antenna connected to it. They arrive via the second antenna to the receiver (RC) where they are converted into an information signal.

The criterion of bulk material presence or absence at a control level in the tank is the degree of radiated radio signal absorption along the path from transmitting to the receiving antenna. In this case during radio signal transmission through bulk material it is at least 3...5 times weaker as compared with the transmission in clear space. It was established experimentally that when a radio signal passes through the layer of cement, ore, crushed stone, sand, coal of 30 - 50 cm and more thickness, it is attenuated by at least 10 times.

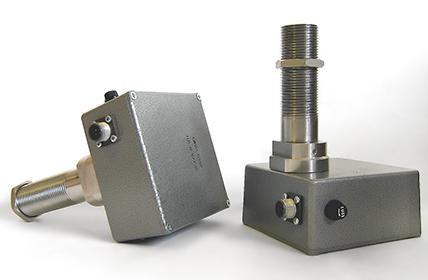

Design versions

Microwave barrier versions are classified by antenna designs

| Barrier of level type |

Designation |

Design features |

| SIUR-03V2.1(f) |

VIGT.407629.021-01 |

On the base of a rectangular brass waveguide (pipe 23×10×1 DKNRT L96), has a brass flange on the flat end |

| SIUR-03V2.1(s) |

VIGT.407629.021-02 |

On the base of a rectangular brass waveguide (pipe 23×10×1 DKRNT L96), has a PTFE plug on flat end |

| SIUR-03V2.2 |

VIGT.407629.022 |

On the base of a circular waveguide of stainless steel 12H18N10T (circular seamless pipe Ø32×2) |

| SIUR-03V2.3(4) |

VIGT.407629.023(4) |

On the base of a circular waveguide of stainless steel 12H18N10T with straight pipe thread 1". Allowable pressure in the silo – up to 10 atm. Connecting of an external cable is made via sealed connector (version 3), or to terminal screw contacts. In this case cable is inserted inside the electronic unit through a sealed lead-in (version 4). |

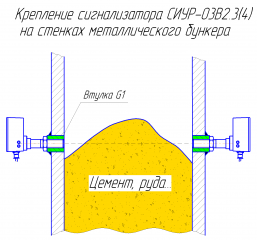

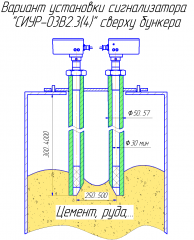

Options of microwave barrier installation

Depending on the object of installation and technological features of production there are several ways to mount level alarm sensors. The alarm can be installed both on the walls of the hopper and at its upper surface. In the latter case steel pipes with an inner diameter of at least 30mm should be used for transmitting of the probing signal to the control level. It should be noted that pipe length and its surface quality are not important.