Moisture meter FIZEPR-SW100.10.X for bulk materials

The moisture meter FIZEPR-SW100 is the world's only non-nuclear moisture meter providing moisture measurement of materials with large fractions (crushed stone, gravel, ore, etc.)

The moisture meter is indispensable in the production of carbonated concrete rubble, moisture of which can be not less than the same of sand (up to 8%).

The FIZEPR-SW100.10.X moisture meter VIGT.415210.100-10.X is designed to measure the moisture of bulk materials in hoppers, dispensers and on conveyors. Controlled materials: crushed stone, gravel, sand, ore, sawdust and wood chips, as well as mixed feed, grain, flour, seeds and other agricultural products.

The principle of moisture meter operation is based on environment sensing using VHF band waves. Such band is chosen since wavelength must be ten times or even more exceed the size of test material granules. Otherwise the probe signal will be attenuated and scattered on inhomogeneities. Unlike microwave moisture meters, in which centimeter wavelength is used, this device can be used for gravel, rubber, wood chips, etc. The moisture meter FIZEPR-SW100 is unique due to its characteristics.

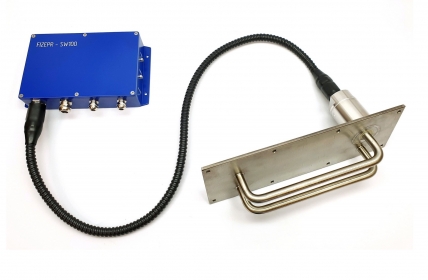

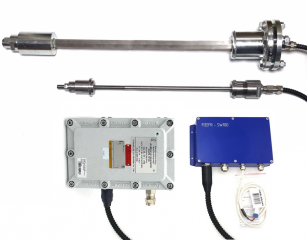

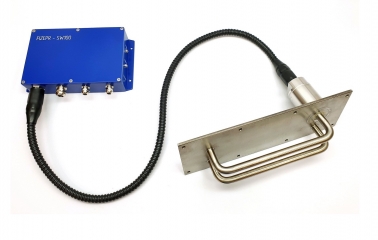

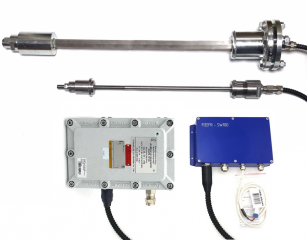

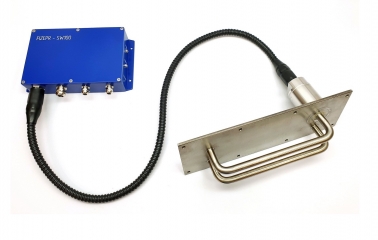

The device consists of an electronic unit and a sensor. The moisture meter sensor includes a probe designed as a stick of stainless steel AISI 321 with a diameter from 14 to 30 mm. This decision determines the exceptional strength and durability of the sensor, resistance to mechanical stress, shocks and abrasive materials.

FIZEPR-SW100.10.4 and FIZEPR-SW100.10.41 moisture meters

FIZEPR-SW100.10.4 and FIZEPR-SW100.10.41 moisture meters  Moisture meter FIZEPR-SW100.10.6

Moisture meter FIZEPR-SW100.10.6

Serial moisture meter sensors for bulk materials are available in two versions with different probe types:

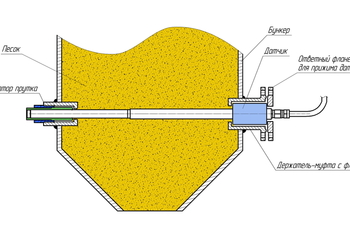

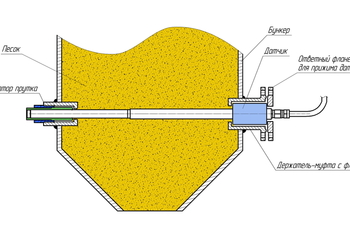

1. The sensor probe is formed as a straight rod with the ends fixed by special couplings on the opposite walls of the hopper. The sensor provides control of the greater volume of material and offers accurate assessment of moisture in the material with inhomogeneous moisture distribution.

Mounting sensors FIZEPR-SW100.10.4 or 10.41 in the hopper

Mounting sensors FIZEPR-SW100.10.4 or 10.41 in the hopper Moisture meter FIZEPR-SW100.10.41

Moisture meter FIZEPR-SW100.10.41

Moisture meter FIZEPR-SW100.10.4

Moisture meter FIZEPR-SW100.10.4

Sensors FIZEPR-SW100.10.4

Sensors FIZEPR-SW100.10.4

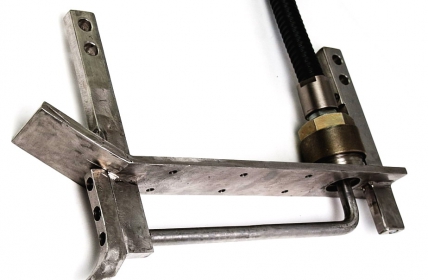

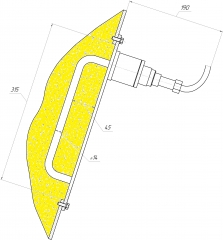

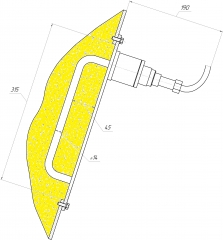

2. The sensor probe is configured as a flat-topped bracket which is mounted on the wall of the hopper via couplings.

Moisture meter FIZEPR-SW100.10.6 or 10.21 in the hopper

Moisture meter FIZEPR-SW100.10.6 or 10.21 in the hopper  Moisture meter FIZEPR-SW100.10.21

Moisture meter FIZEPR-SW100.10.21

FIZEPR-SW100.10.2

FIZEPR-SW100.10.2  FIZEPR-SW100.10.2

FIZEPR-SW100.10.2

Both versions are used both in hoppers and conveyors.

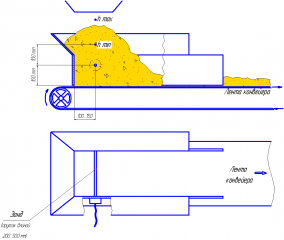

The sensor with a flat-topped probe is mounted above the conveyor belt as shown in the pictures and video (see above). The stream of bulk material is limited by guide plates on both sides and by the panel on top. This stabilizes the material density in the measurement area and significantly improves the measurement accuracy.

Videos showing the use of moisture meters are posted on YouTube.

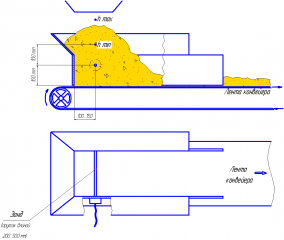

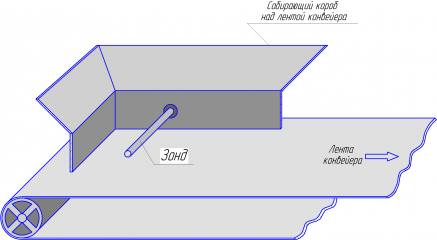

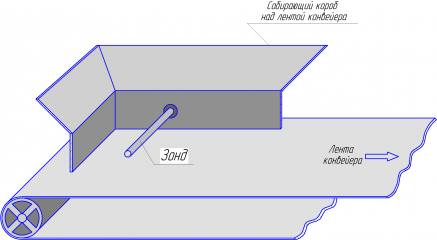

If the bulk product is loaded on the conveyor from above then the collecting duct with a direct probe should be mounted in the loading area above the belt. The probe is mounted in couplings on the duct walls as it shown in the figures below.

FIZEPR-SW100.10.41

FIZEPR-SW100.10.41  FIZEPR-SW100.10.41

FIZEPR-SW100.10.41

Measured material must completely cover the probe. The material layer thickness above the probe should be at least 10 cm high. Required hump elevation of material loaded can be achieved by adjusting the conveyor speed as well as by installing on the duct outlet an extra flap partially overlapping flow. Since the probe is formed as a threaded stick and its length can be adjusted within a wide range (50 to 20-100cm), the level of the material can also be adjusted by changing duct width.

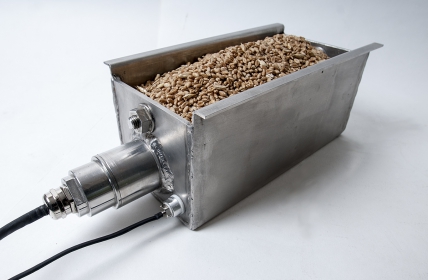

This version of bulk materials measurement solved common problem of sawdust moisture control in the production of pellets.

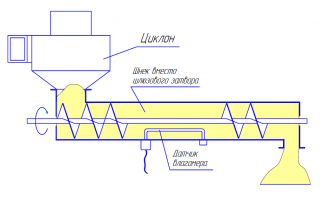

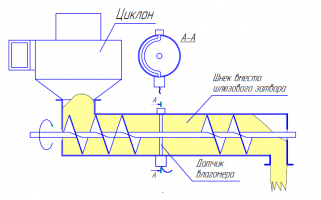

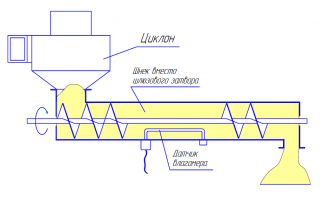

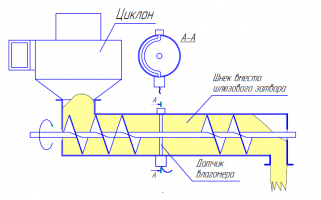

Sawdust moisture can also be controlled in the screw. The moisture meter probe mounted in the screw as shown in the following figures will always be in the area of material with a stable density. In this version the screw acts as a floodgate at cyclone outlet.

FIZEPR-SW100.10.6 sensor in the auger

FIZEPR-SW100.10.6 sensor in the auger FIZEPR-SW100.10.43 sensor in the auger

FIZEPR-SW100.10.43 sensor in the auger FIZEPR-SW100.10.6 sensor in the auger

FIZEPR-SW100.10.6 sensor in the auger  Moisture meter FIZEPR-SW100.10.43

Moisture meter FIZEPR-SW100.10.43

SUITABLE FOR ANY MATERIAL

The moisture meter FIZEPR-SW100.10.X for bulk materials is a VHF band radio device. Such choice of wavelength range allows using the device for measuring moisture of inhomogeneous materials, bulk materials with large (5 cm and more) granules: crushed stone, gravel, ore, rubber chips, wood chips, etc., agricultural products. For example, FIZEPR-SW100.10.X can be used as a sand moisture meter, a crushed stone moisture meter, and a gravel moisture meter.

Unlike microwave moisture analyzers, the FIZEPR-SW100.10.X provides high accuracy of measurement by averaging measurement results over the entire material volume.

HIGH RELIABILITY

Construction of the sensor is leak-proof and provides high reliability and mechanical stability.

Using of stainless steel and ceramic seals provides resistance to corrosion and the possibility of probe application in drying machines with temperatures more than 200 °C.

Moisture meter FIZEPR-SW100.10.16

Moisture meter FIZEPR-SW100.10.16

Since December 2017, the production of moisture meters FIZEPR-SW100.10.16, designed to measure the humidity of anthracite, has been started. These devices can also be used to measure other loose materials that are characterized by high electrical conductivity, for example, soda, aluminum hydroxide, certain types of ore, NaCl salts, KCl and other materials.

Warranty period is 24 months.

MOISTURE METER FOR ANY CONDITIONS

The moisture meter probe can be mounted on the walls in the hoppers, in pipelines or on trays in conveyors. The probe is mounted in steel plug holders, which are welded to the wall of the hopper, tray or piping. The probe can be easily inserted and removed through the holes in holders.

Wide range of sensor sizes

The range of possible probe sizes varies from 20 cm to 1.5 m. The long probe provides averaging of measurement results over the entire volume. Moisture differences in local areas do not lead to errors in the moisture measurement.

Possibility of integration in ACS systems

The moisture meter is suitable for installation on concrete product plant dispensers to control the moisture of carbonate rubble, granite gravel and sand. Using of the moisture meter is the most effective when it is operated as a part of the automated concrete mixing plant system. According to the results of sand, crushed stone and gravel moisture measurements, the ACS automatically adjusts the dose weight of inert components and water. This significantly improves the quality of mixtures and reduces the loss of time on their correction.

No radioactive materials

The moisture meter does not contain any radioactive materials. This makes it safe to use and frees the customer from the need to ensure radiation safety, as well as from expenses for nuclear devices disposal. Moreover, there is no need to obtain a license for handling devices and machines generating ionizing radiation.